Services

The Engeco approach to projects

encompasses these four phases

Mix Design

We define the most suitable mix design for the types of construction site and it's needs, with checks on fresh mixes. The aim is to safeguard all the concrete so that it remains waterproof with limited cracks in the points analysed by Engeco engineers.

Data

Indicative mix design and concrete requirements

- Resistance class: complies with the specifications of the executive project (frequent: C25/30 - C30/37-C32/40........);

- Exposure class: complies with the specifications of the executive project (frequent: XC2-XC4);

- Consistency: S4 / S5

- Maximum water / cement ratio: 0.50 +0.45;

- Maximum penetration depth of water: <20 mm according to UNI EN 12390-8 standard;

- Recommended types of cements: 32.5, cements with fly ash additions are also preferred;

- Mix Design with sufficient quantity of fine components (s 100 um) such as to allow easy and homogeneous compactability '440480Kg / m3: cement + finidegli aggregates + cenerivolanti and / ofiller.

- Additives: superplasticisers and possibly shrinkage compensators;

- Further specifications, if necessary for the specific project, will be indicated together with the offer and will be a substitute for those indicated above.

- "Ad hoc" design mix for highly stressed special structures, for very low hydration cis with At controlled for large casting thicknesses, for structures in seismic areas, for structures waterproof to radon gas, for structures with very rapid disarmament and structural usability, for other structures according to particular design requirements.

| -SIA 118/272 | General conditions for waterproofing and drainage of structures under terrain and underground construction |

| -SIA 118/274 | General conditions for sealing joints in buildings |

| -EN 206-1: 2006 | Concrete - Specification, Performance, Production and Compliance |

| -UNI 11104 : 2004 | Concrete - Specification, performance, production and conformity - Complementary instructions for the application of EN 206-1 |

| -EN 934-2 | Additives for concrete |

| -EN 12620 | Aggregates for concrete |

| -EN 450-1 | Fly ash |

| -EN 12390-8 | Intrinsic impermeability of concrete (5 bar for 3 days <20 mm) |

| -EN 12350-4 | Homogeneous compaction of the concrete (referred to casting conditions without segregation and bleeding) Compaction on site 2 98% of what can be obtained on the reference laboratory specimens for mechanical strength |

-

CLS Guide download pdf

-

Prequalification example download pdf

-

Example of fresh tests download pdf

-

Example on fresh and hardened download pdf

-

Example of fresh and hardened tests download pdf

-

Example of fresh and hardened tests download pdf

-

Example of fresh and hardened tests download pdf

Requirements for installation, taken from "Guidelines for the implementation of structural concrete and for the evaluation of the mechanical properties of hardened concrete by means of non-destructive tests" issued by the Higher Council for Public Works - Central Technical Service, February 2008.

Complete avoidinance of casting on partially or totally hardened concrete

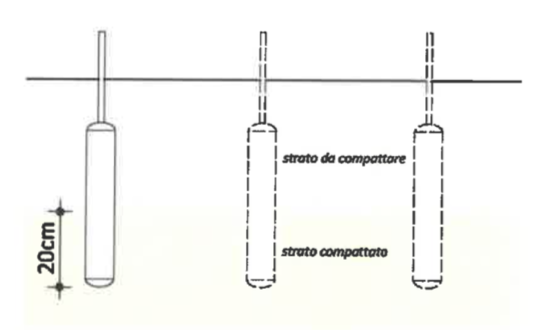

Compaction:

- La compottoztone dord essere efficace ed impedire la formazione di nidi di ghialo

- The times of Immersion of the soror vibrator commisurud to the consistency of the concrete

- The distance of the pund for the vibrators and depending on the type of vibrator used

- And it should be difficult to compact the entire volume of the concrete put into the works

- Vibrator must always be immersed for 20 cm omni in the lower layer of fresh anchors, thus allowing the cohesion of the two layers

| Vibrating needle diameter [mm] | Effective range | Distance between the diving points [cm] |

|---|---|---|

| 40 fino a 60 | 30 | 25 |

| > 60 | 80 | 70 |

The executing company is directly responsible for the formation of gravel nests, it will be the responsibility of the undertaking to take all the necessary precautions so that their training is excluded.

| Cause | Solution |

|---|---|

| Projectual: section with strong congestion of the armor irons, lack of space for the introduction of the vibrators | adapt armor layout |

| Formwork: non-sealed joints that allow the release of water | adapt formwork |

| Properties of fresh concrete: lack of fines, poor workability or excess of water, hardening in advance, maximum diameter of the aggregates large in relation to the size of the casting | correct mixture |

| Implementation: concrete left to fall from an excessive height, excessive load of concrete in the formworks. Non-existent or ineffective loading hoppers, horizontal displacement of the concrete | correct implementation |

| Compaction: vibrators that are undersized for power, frequency or amplitude, vibration time too short or excessive, excess distance between vibration points, insufficient number of vibrators | correct use of vibrators |

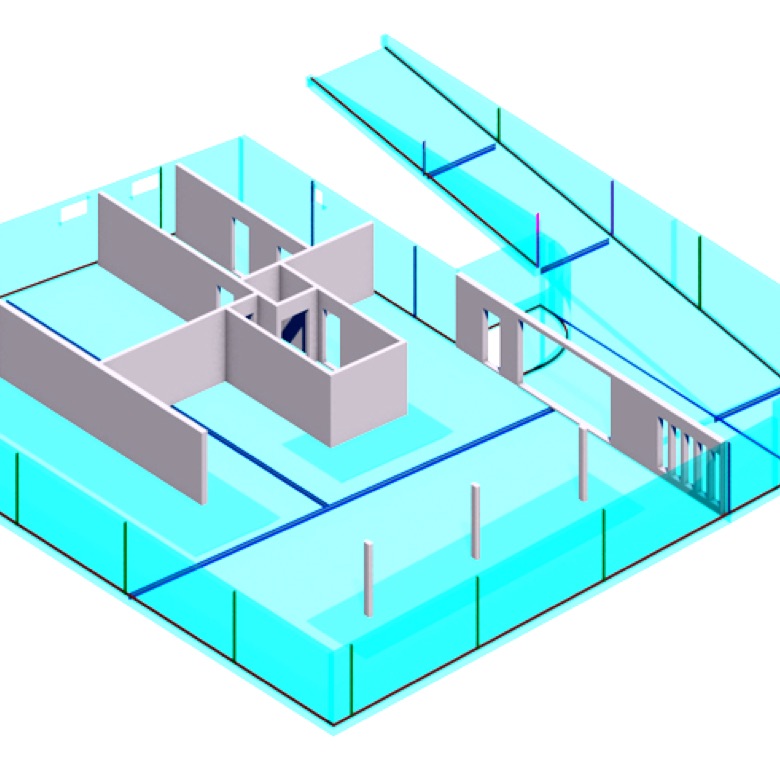

Quality Control And Assistance

During the construction of an Engeco White Tank system, rigorous on-site checks are always scheduled for the execution of the work, with a dedicated and specialised support team.